Iron Oxide Pigment Fe2O3 Red Black Yellow Blue Color for Brick Concrete Painting

Makes Your Life Colourful

Our iron oxide pigments are the perfect solution for all your coloring needs. Our pigments are made with the highest quality iron oxide and are available in a wide range of colors to suit any project.

Whether you are looking for a high quality pigment for your concrete coloring or need a reliable and durable material to meet your plastic or paint coating needs, our iron oxide range is the perfect choice for you.

We provide free samples, you can choose 300g or 500g, you can also choose a variety of colors, according to your needs to send samples!Contact us today to learn more about our products and how they can benefit your business!

Application

Iron oxide pigments are a popular colorant used in a variety of industries due to their excellent color stability, durability, and non-toxic nature. Iron oxide pigments are produced by oxidizing iron in a controlled environment, resulting in a range of colors from yellow to red to black.

Iron oxide pigments are widely used in the construction industry to color concrete, asphalt, and other building materials. They are also used in the paint and coatings industry to provide color and protection to surfaces. In the plastics industry, iron oxide pigments are used to color plastic products such as toys, automotive parts, and packaging materials.

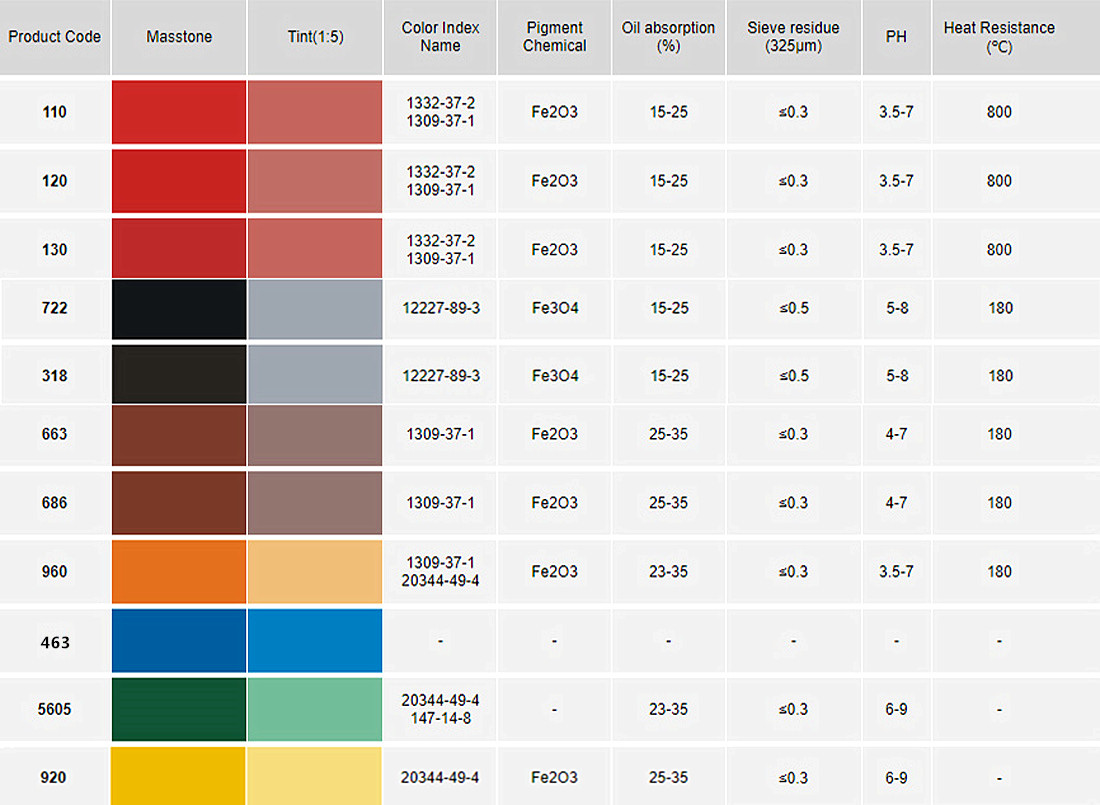

Shade Card (Technical Data)

Concrete Cement Pigment

Iron oxide is used in the field of concrete, and it uses the excellent weather resistance, alkali resistance and light resistance of iron oxide. These functions are not available to other inorganic pigments or organic pigments.

Iron oxide pigments are used as pigments or colorants for prefabricated parts and building products in various types of concrete, and are directly transferred into cement for application, such as walls, floors, ceilings, pillars, porches, pavements, parking lots, stairs, stations, etc.; Various architectural ceramics and glazed ceramics, such as face tiles, floor tiles, roof tiles, panels, terrazzo, mosaic tiles, artificial marble, etc.

Paints & Coatings Pigment

Iron oxide pigment is widely used in coatings, paints and inks due to its non-toxic, non-permeable color, low cost, and can form a variety of different tone characteristics. Coating is composed of film forming substances, pigments, fillers, solvents and additives. It has developed from oily paint to synthetic resin paint, all kinds of paint are inseparable from the application of pigment, especially iron oxide pigment has become an indispensable pigment for the paint industry.

Suitable for all kinds of paint coloring and protection materials. Such as amine alkyd, vinyl chloride resin, polyurethane, nitro, polyester paint and so on. It can also be used in water-based coatings, powder coatings and plastic coatings. And used for toy paint, decorative paint, furniture paint, house paint, garage paint, parking lot paint, car finish paint and so on.

Rubber & Plastic Pigment

Iron oxide pigments are widely used in the plastics and rubber industries due to their excellent color stability, heat resistance, and UV resistance. These pigments are commonly used to color a wide range of plastic products, such as PVC pipes, toys, automotive parts, and packaging materials. The use of iron oxide pigments in plastic products not only enhances their aesthetic appeal but also improves their durability and resistance to weathering.

In the rubber industry, iron oxide pigments are commonly used to color a variety of rubber products, such as tires, conveyor belts, and hoses. The use of these pigments in rubber products helps to improve their resistance to heat, UV radiation, and weathering, thereby increasing their lifespan and performance.

Ceramic Pigment

Iron oxide pigment has been widely used in many industries because of its characteristics of wide spectrum, tasteless, non-toxic and cheap. The ceramic industry is no exception. In recent years, with the development of ceramic industry, the amount of iron oxide pigment in ceramic industry is also increasing year by year.

Ceramic products are mainly divided into seven categories: architectural ceramics, sanitary ceramics, garden glazed ceramics, art ceramics, daily ceramics, industrial ceramics and special ceramics. Iron oxide pigment is widely used in these seven categories of ceramic products.

Leather Pigment

One of the primary advantages of iron oxide pigments is their ability to produce a wide range of colors, including red, yellow, brown, and black. This makes them ideal for use in leather dyeing and finishing processes, where color consistency and durability are essential.

Iron oxide pigments are also highly resistant to fading and weathering, making them ideal for outdoor leather products such as boots and jackets. They are also resistant to chemicals and UV radiation, which ensures that the color of the leather remains vibrant and attractive for a long time.

In addition to their coloring properties, iron oxide pigments also have excellent hiding power, which means they can cover imperfections and blemishes on the leather surface.

Paper Pigment

Iron oxide is second only to titanium dioxide inorganic pigment, is also the first color inorganic pigment. In the total consumption of iron oxide pigment, more than 70% is prepared by chemical synthesis method, known as synthetic iron oxide. Synthetic iron oxide due to its high synthetic purity, uniform particle size, and wide spectrum, color, inexpensive, non-toxic, has excellent coloring and application performance, with uv absorption and other properties.

Iron oxide pigment can be used to Paper. Synthetic iron oxide yellow & black used extensively for preparation of paper colourants. Those are totally free from heavy metals and hence preferred by the industry.

Fertilizer Pigment

Iron oxide pigments are widely used in the field of fertilizers due to their excellent color stability and resistance to weathering. These pigments are commonly used to color fertilizers, such as granular fertilizers, liquid fertilizers, and micronutrient fertilizers.

The use of iron oxide pigments in fertilizers not only enhances the aesthetic appeal of the product but also helps in identifying the type of fertilizer and its nutrient content. In addition, iron oxide pigments are also used in the production of slow-release fertilizers, which provide a sustained release of nutrients to the plants over an extended period of time.